Production under control - production information system MES/MOM PRODIXI

Continuous real-time monitoring and control of production and long-term storage of all information collected. Tools for production analysis to increase production efficiency and profitability of production processes. MONITORING AND CONTROL

MONITORING AND CONTROL

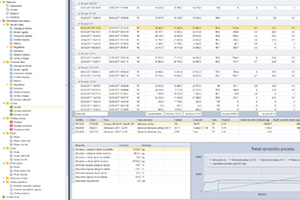

PRODUCTION MONITORING AND CONTROL

Data collection, data-mining and real-time evaluation. Staff records on production lines and individual workplaces. On-line evaluation of production equipment status, number of operators and projection of these facts into production plan.

PLANNING

PLANNING

PRODUCTION PLANNING

Creation of production plan, human resources plan and shutdowns according to production equipment definitions and their grouping including planning of packaging materials for your products. Possibility of managing revenue, shipping and shipping.

EVALUATION

EVALUATION

TRACEABILITY, KPI, REPORTING

Comprehensive recording of product manufacturing data during the manufacturing process. Easy traceability in case of complaints or audits. Evaluation of key production indicators. Possibility to create production and management reports.

Why choose PRODIXI?

Until you measure, you don't know where you're losing.

It is a system built to the needs of your company. The many years of experience gained during the realization of projects in almost all industrial sectors give us the necessary perspective to realize such a product that brings demonstrable benefits, savings in organizing production and its maintenance. Provides manufacturing and statistical data to make your production processes as efficient as possible.

Unique identification of workers

Employee registration by personal cards at individual workplaces. Watch on every machine who works on it, who is responsible for producing a particular product. Watch how long it takes the maintenance staff to start troubleshooting and how long it takes to remove it.

Product identification, traceability

Record the important production parameters of your products during production. Validate their manufacturing parameters with the manufacturing instructions. Keep complete records of all manufactured products, including tracing them in your production history.

Staff training under control

Organize all trainings - entry, repetition including documentation centrally through the web application of the system including electronic evidence of each employee's participation. Keep under control who participated in what training and how long the training lasted.

Quality assurance in the first place

Get a tool to fight your customers' complaints. The system can automatically alert you to the necessary quality training - corrective actions. It enables the planning and recording of these training courses to quality personnel with the possibility of assigning them to a specific production line workplace.

Operator qualification tracking

Employee tracking and working time at each workplace allows automated creation of a qualifying matrix. Only sufficiently qualified workers will be allowed to work on a particular workplace separately. Others can go through the necessary training under the supervision of a coach.

Minimizing paper records

Replace all printed and hand-filled forms, shift records, quality records for the electronic version. Minimize the amount of time needed to manually fill in the necessary evience and automatically generate all reporter reports. MES collects all the necessary data and can convert it to the desired format itself.

Control, records, alerts

Checking compliance with legal requirements for breaks. Ensure alerts when workers have to rotate between workplaces or start breaks. Checking adherence to prescribed times, including records of all records.

Documentation in one place

Central management of your equipment documentation, whether it's work instructions or project documentation for maintenance personnel. Easy addition of documentation via web interface to selected production lines - specific workplaces, etc.

Environment Industry 4.0

Interconnection of production equipment and information technology increases productivity and competitiveness. In Industry 4.0, all information is available everywhere and at any time. Data-mining and subsequent analysis of acquired data serve to optimize production processes. It is a way to increase productivity, increase production quality and profitability.

Even existing production lines and machines can be integrated with Industry 4.0 with minimal cost. Modernizing control systems or complementing communication interfaces is often enough to provide the necessary data exchange with open standards in IT systems.

Need something more?

LAST IMPLEMENTED PROJECTS

Implementation and delivery of industrial operator panels designed for production planning and production line production. Employee attendance, security breaks and workplace rotation. Complete documentation and training materials management.

Implementation and delivery of MES PRODIXI production information system for the customer in the production of asphalt mixtures. Production Line Monitoring, Production Records and Production Process. Complete management of production recipes and production records using MES application in server / client mode.

Implementation of MES PRODIXI for data collection from all stations, production control of components for individual stations and refurbishment workplaces including administration and central label printing.